联系永龙

咨询热线021-57566219- 手机:15900658318

- 传真:021-57568296

- 邮箱:1257073858@qq.com

- 地址:上海市奉贤区南亭公路

- 2788号

液化气EN(干式接头)13175加注标准

时间:2020-10-29 13:12:43 来源:永龙阀门 阅读:0次

液化气EN(干式接头)13175加注标准

液化烃

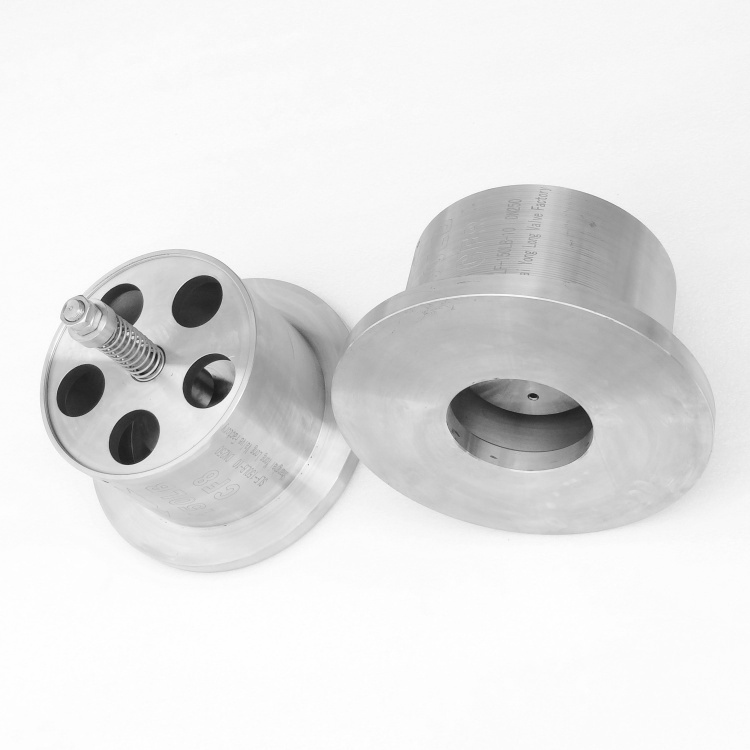

New Coupling to meet LPG Tanker Standard

符合液化气罐车加注标准的自密封干式接头

继欧盟27国之后,超过30个国家采用了DGC液化气自封加注形式

As per a Bulletin issued by the Liquefied Petroleum Gas Safety Association of Southern Africa (LPGSASA) and further legislated by the Department of Employment and Labour, Cam-and-Groove type Couplings are no longer permitted for use in gas tanker applications and should be replaced with a suitable Dry Break Coupling System. The industry has until 30 September 2020 to conform.

根据南非液化气安全协会(LPGSASA)发布的公告以及劳动就业部的进一步立法,液化气罐车已不再允许使用双扣式开放接头,而应当更换合适的干式接头系统。全行业必须在2020年9月30日前达到此标准。

Several incidents involving Cam-and-Groove type couplings have driven this change placing the onus on all industry players to address the risks associated with the use of this type of end-fitting and make the legislated changes.

双扣式接头引起的几起事故推动了这一变化,液化气行业的所有参与者都有责任解决由于使用开放式接头引起的风险并进行法律更新。

The Dry Break Coupling System will ensure that your fleet is not only legal and compliant to international standards but will ensure the safety of your Staff, your Assets and the Environment. Whilst the shift comes at a cost, increased productivity provides a short payback and an attractive return on investment.

干式接头系统不仅将确保您的车队是合法运营、符合国际标准的,而且能确保您的工作人员、您的资产与环境的安全。尽管这一转变需要付出一定代价,但生产率提高能带来短期的投资回报以及诱人的投资收益。

Jachris, Africa’s largest supplier of Hose and Couplings, has a range of products to assist you in this regard which includes but is not limited to Dry-Break Couplings (Hose and Tank Units), Tank Unit Pressure Caps and LPG Suction & Delivery Hose.

Jachris是非洲最大的软管和接头供应商,在这一方面有一系列的产品可以为您提供帮助,包括但不限于干式接头(公头端和母头端),公头压力保护盖与液化气排吸软管。

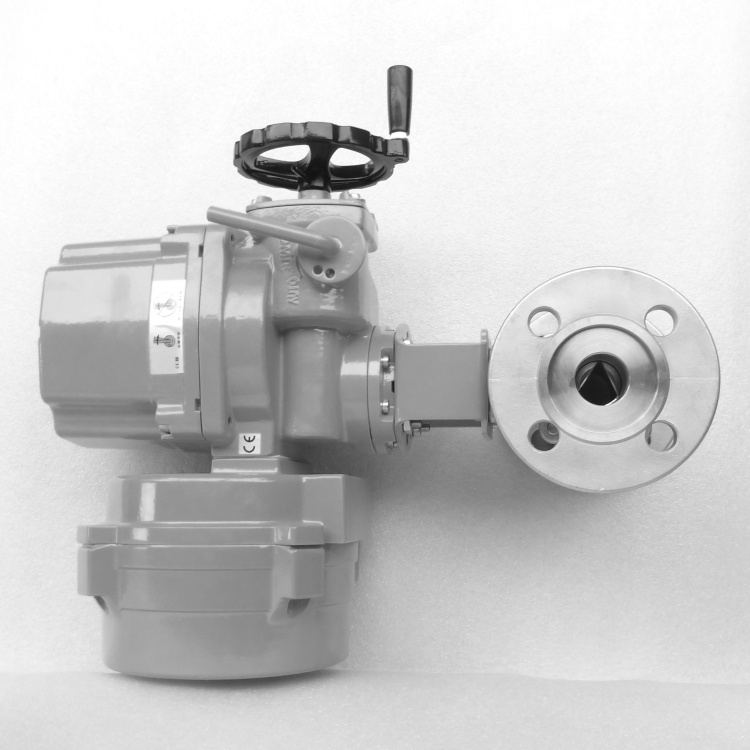

Jachris proposes the use of a 3-inch coupling with a 2-inch flange to meet the new South Africa National Standard 1518, which is in line with international LPG safety standards. The new regulations were promulgated at the end of March providing a deadline of 1 October for all South African refineries to only fill LPG tankers fitted with new Dry Break Couplings. This means that industry must change its LPG equipment and coupling components over the next few months as refineries will no longer fill any that are still using Cam-and-Groove couplings.

建议使用带有2寸法兰末端接口的3寸干式接头,以符合南非1518国家标准,该标准同时符合国际液化气安全标准。3月底颁布的这些新条例规定南非所有炼油厂必须在10月1日截止日期之前通过换装干式接头的罐车进行液化气装卸。这意味着液化气行业必须在接下来的几个月内更换其液化气设备和接头配件,因为炼油厂将不得再使用双扣式接头进行液化气加注。

The LPG industry took a positive decision on the sizing of the Dry Break Couplers. The current Cam-and-Groove systems are all 2-inch while the international standard changed to 3-inch for liquid filling and 2-inches for vapour. The majority of the LPG tankers in South Africa are fitted with 2-inch valves and piping, and changing the liquid filling to 3-inch is a potential challenge. Jachris, in partnership with their supplier Manntek of Sweden, designed a suitable 3-inch tanker unit complete with a 2-inch flange to suit the existing tanker valve flanges, resolving most of the technical challenges for the tanker owners by avoiding a complete system rebuild.

液化气行业对干式接头的尺寸做出了一项积极的决定。当前的双扣式接头系统均为2英寸,然而国际标准已将液体加注更改为3英寸,将回气管路更改为2英寸。南非的大多数液化气罐车仅装有2英寸的阀门和管道,因此将加注更改为3英寸是一个潜在的挑战。Jachris与其瑞典供应商Manntek(曼太柯)合作,设计了一个合适的配有2寸法兰末端的3寸公头,以适应现有的罐车阀门所带的法兰接口,避免了整个系统的改造,从而解决了罐车所有者面临的大部分技术问题。

The reasons for the change include that Cam-and-Groove couplers are not safe in LPG applications and have resulted in fatalities in South Africa. LPG filling takes place at approximately 25 bar of pressure and when strict operational procedures are not followed, Cam-and-Groove couplers can be potentially fatal. A coupling under pressure that comes loose due to poor clamping/crimping, failure to follow the required operational procedures or unplanned disengagement between tanker and port can cause serious injury or even death to the operator. Furthermore, Cam-and-Groove couplers also lead to excess spillage compared to the Dry Break Couplers and can contribute to the loss of thousands of Rand worth of LPG per tanker per year.

做出这一改变的原因在于在液化气的应用中,双扣式接头并不安全,已经造成南非多起死亡事故。在25bar左右的压力下,液化气会发生泄漏;如果未遵循严格的操作程序,双扣式接头可能是致命的。由于压接不良而导致载压环境下的接头松动,未遵循操作程序或罐车与接收站的脱离可能严重伤害操作者甚至造成人身伤亡事故。此外,与干式接头相比,双扣式接头可能会导致液化气的过量泄漏,并且可能造成罐车每年数千兰特(南非货币单位)液化气的损失。

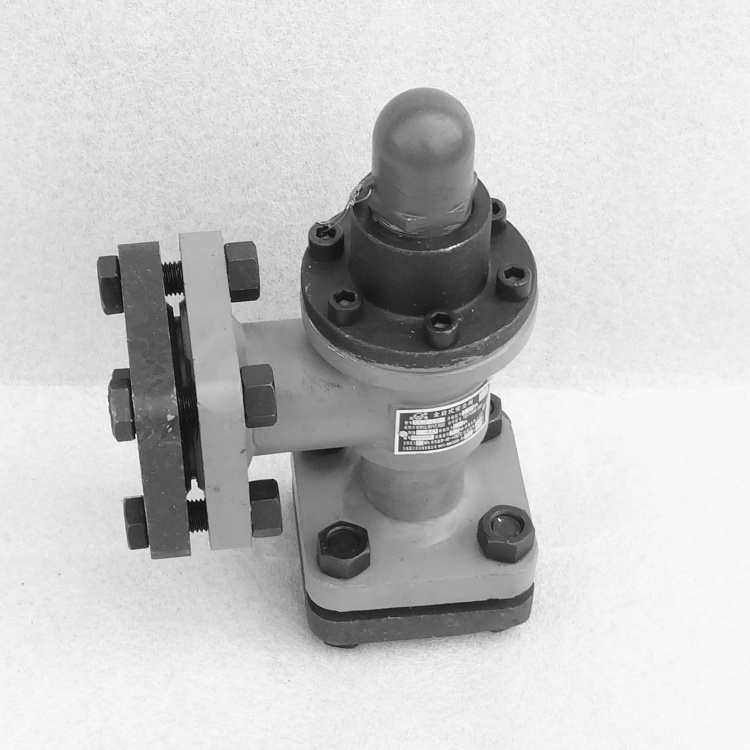

Dry Break Couplings are used to prevent excess spillage. They protect people and property from dangerous and costly exposure by keeping hazardous liquids and vapours in-line and out of the environment. Dry Break Couplings are used at liquid or vapour transfer points where you do not want product loss. Using Dry Break Couplings will reduce the hazards typically found when handling or processing LPG. These couplers also allow spill-free handling for loading and unloading tank trucks, rail tankers and tank containers. This minimisation of spillage and product loss keeps the environment free from hazardous vapours and liquids.

液化气干式接头能防止超预期泄漏,保护人员和财产免受液化气爆炸产生的损失。如果您不想气体或者液体滴漏,可以在气液相的接驳处使用干式接头。干式接头的采用将会降低处理或加工液化气时通常会发生的危险。这种类型的接头同样能保证公路罐车、铁路罐车和罐式集装箱的无泄漏装卸。泄漏与液体物料损失较小化可以使环境免受有害气体和液体的影响。

Preliminary investigations have revealed that in South Africa and surrounding Southern African Development Community (SADC) countries, there are approximately 300 tankers that must be converted. Most South African tankers are built with 2-inch piping systems on the trucks with corresponding 2-inch safety valves. The major concern associated with changing to 3-inch liquid filling was that some serious size adaptors would be required from 2-inch to 3-inch to make the change possible, adding complexity and cost. Fortunately, the valve and pipes will not be required to change as the size change does not make it incompatible. Certain flow restrictions would occur, but it would only nominally reduce the full potential of a 3-inch line. Most tankers would require a minimum of one 3-inch liquid fill tanker unit and one 2-inch vapour tanker unit. A full 3-inch pipeline and valve system would provide a time filling advantage. The new tankers that will be built in South Africa or imported will be built according to new size and standards.

初步调查显示,在南非以及周边的南非发展共同体(SADC)国家,目前大约有300辆罐车必须要改装。南非大多数的槽罐车装配的都是2寸的管道系统以及配套的2寸安全阀。而更改成3寸的液体加注会带来一个主要问题,即需要一些尺寸较大的母头(2寸至3寸)才能进行更改,这样一来就会增加复杂性与成本。幸运的是,由于尺寸改变不会使其不兼容,无需更换阀门和管道。尽管有一定的流量会被限制,但名义上只会降低3寸管道的流量。大多数的罐车至少需要一个3寸的液体加注公头和一个2寸的气体用公头。使用3寸的管道和阀门系统将会在加注时提供时间优势。南非将会根据新的尺寸与标准建造或进口新的罐车。

At refinery level, the filling stations or bays would have to potentially be supplied with new hose assemblies fitted with female hose Dry Break Couplers, but we anticipate that these will already be in place by now. Fortunately, there are far fewer filling points in a refinery that would require new hose assemblies than there are tankers requiring new coupling systems.

炼油厂必须要为加气站提供新的软管总成,该总成需要装配带有内螺纹的干式接头,但我们估计这些设备已经安装到位。幸运的是,与需要新接头系统的罐车相比,在炼油厂,需要新软管总成的加注点(母头端的应用)要少得多。

There should be no barriers to installing the new couplers. While the initial capital outlay could be perceived as high, data proves that the efficiency gains outweigh the cost of conversion significantly with a noticeably short payback period. This is before one even considers the improved safety and environmental conditions created by the legislated change.

安装新接头应该没有任何障碍。尽管最初的资本支出可能会很高,但数据证明,效益的提高远远超过更换成本,投资的回收期非常短。在此之前,人们甚至未曾考虑通过变更立法带来安全与环境条件的改善。

The Dry Break Coupling Systems are generally usable across different gas or fluid types with the exception of a seal kit change. Coupling Systems can often be colour-coded or keyed specifically to avoid the mismatching of hose/couplings for their respective media.

此外,更换密封件,干式接头系统可用于不同的油品或液体。干式接头可以专门进行颜色/机械编码以避免不同介质软管和接头的错误对接。

【推荐阅读】 / TECHNICAL ARTICLES

- + “得理饶人,才是大气”-上海氨气阀门厂2020-05-10

- + 阀门定位器-韩国Rotork YTC公2020-08-20

- + 国外阀门究竟有何优势?-上海气动球阀品2020-05-10

- + “2019氨市销售市场的波动变化”-上2020-05-10

- + 水处理技术简史 | 零排放2020-09-01

- + 瀚柏尼Habonim-以色列气动执行器2020-09-25

- + 温州阀门标准化战略重大试点项目沟通会顺2020-10-13

- + 氨制冷剂不该被“错杀”-上海液氨阀门厂2020-05-10

- + 第十届中国国际流体机械展!近200家阀2020-05-10

- + “2019安全生产基础司工作要点”-上2020-05-10